- Home

- Marking Products

- Dot Peen

- 3000 Column mounted Z Axis and Verifier Machine

PORTABLE

BENCH MOUNTED

INTEGRATED

3000 Column mounted Z Axis and Verifier Machine

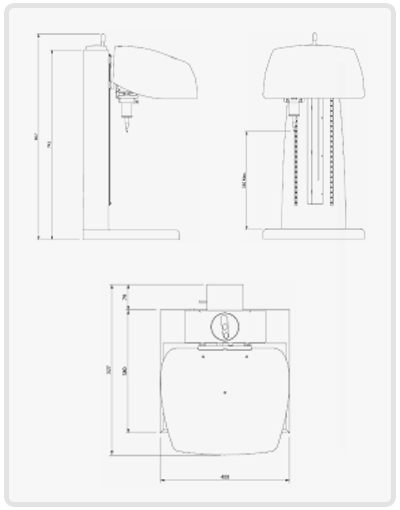

3000 C60-60ZAV | 3000 C100-100ZAV | 3000 C150-150ZAV | 3000 C300-150ZAV

Fully programmable electromagnetic dot peen marking machine, with integrated DataMatrix Verification system.

- Rigid column and robust ball screw mechanism (twin linear guiding rails and twin linear bearings on each axis) guarantees dot precision required for the most demanding industrial part identification applications

- Powered Z digital axis with Autosense system (ZA model) allowing self adjustment to variation of part batch height with the best precision, repeatability and consistency (especially well suited to Data Matrix marking)

- Large marking envelope up to 300×150 mm

- Electric Solenoid with programmable depth settings. Capable of marking all engineering materials up to 62HRc (800Hv)

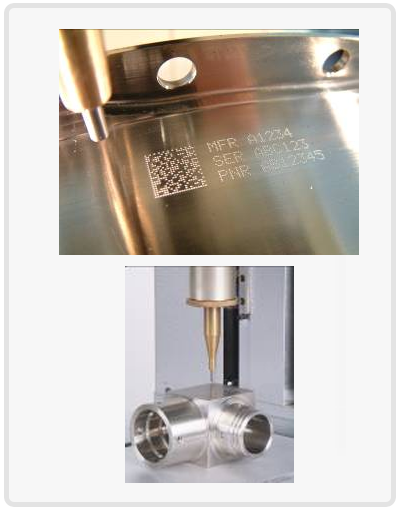

- Integrated DataMatrix mark quality and syntax verification camera. Provides in-process verification with machine condition feedback.

- Verifies to international standards AS9132, JES131, AIM-DPM-Guideline, MIL-STD-130, ISO15434, ISO16022.

- Capable of Marking and Verifying a 22×22 UID compatible DataMatrix in an area less than 4mm square (Dependent on surface finish).

- Simple to use operator software user interface compatible with other marking technologies including Laser, Electro Chemical Etching and Bag & Tag label printing. (Mark2Verify™)

- 100 – 220v single phase supply (no pneumatics required).

- Optional work table with lockable cabinet for control system and PC, fixture draws and keyboard drawer.

- Low running costs and virtually no consumable costs.

VeriSmart™ Verifier and Mark2Verify™ software

- The latest Pryor VeriSmart camera features a 5 mega-pixel imager ensuring the system can verify the widest range of different size codes without the need to change lenses.

- The camera unit is specifically designed to be mounted on to the marking machine. Its robust construction, unique shrouding and software controlled DOAL (Diffused on axis lighting) ensure long term, consistent high quality images are maintained during in-process verification.

- The Mark2Verify™ software provides a very simple data entry and verification result user interface, with many advanced features available to the system administrator.

- Simple traffic light feedback to the operator, reporting green for a compliant mark, amber for compliant but attention required and red for non-compliance either from mark quality or data formatting within the DataMatrix code.

- Machine condition feedback providing users and administrators with Fault, Cause and Solutions if amber or red lights are shown during verification.

- Powerful data entry functions ranging from simple prompted keyboard entry, barcode only entry, unique serial number generation, text file capture from LAN/ERP systems, direct SQL database queries and vbscripting for customised data entry.

- Advanced Database functions allow all marked data to be logged with all verification results and images. This provides duplicate checking functions to ensure serial numbers are never duplicated and allows verification reports to be generated. These reports can be despatched with the part to prove successful mark verification.

- Simple to configure user/password access, allowing administrators lock out all configuration screens and provide individual users with various levels of privileges.

- Wide Range of Options

Technical Specification

- Simple traffic light feedback to the operator, reporting green for a compliant mark, amber for compliant but attention required and red for non-compliance either from mark quality or data formatting within the DataMatrix code.

- Machine condition feedback providing users and administrators with Fault, Cause and Solutions if amber or red lights are shown during verification.

- Powerful data entry functions ranging from simple prompted keyboard entry, barcode only entry, unique serial number generation, text file capture from LAN/ERP systems, direct SQL database queries and vbscripting for customised data entry.

- Advanced Database functions allow all marked data to be logged with all verification results and images. This provides duplicate checking functions to ensure serial numbers are never duplicated and allows verification reports to be generated. These reports can be despatched with the part to prove successful mark verification.

- Simple to configure user/password access, allowing administrators lock out all configuration screens and provide individual users with various levels of privileges.

- Wide Range of Options

Application

- Direct Part Marking (DPM)

- IUID MIL130 Compliance marking

- Programmable marking

- Component identification

- Component traceability

- Serial numbering

- Logo marking

- Security marking

- Health & safety appliance marking

- Certification marking

- Time and date marking

- Part numbering

- Batch and shift coding

- Calibration systems

- Label and tag marking

The Marktronic MarkMate has been designed to offer the flexibility and benefits of dot marking technology in a low cost, simple to use package.

The build quality and mark precision are second to none for this type of machine.

The MarkMate consists of three basic building blocks, marking head, base & column and the controller.

The Marking Head is available in a large 100 x 75mm size, being driven by an accurate lead-screw arrangement. For components requiring a deeper mark there are 9 levels of force to choose from. The marking styli are available in a range of lengths to suit different applications.

The Base and Column facilitate the manual z-axis adjustment to allow for components of differing heights.

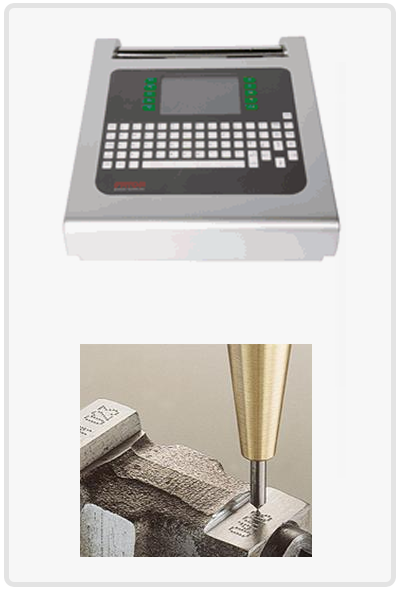

The Controller is a separate unit to ensure it is protected from the mechanical shock loading of the marking operation. The easy to use software allows for 5 font types and up to 600 layouts to be stored. Available in a variety of languages (including English, French, German, Spanish, Swedish, Finnish, Italian, Cyrillic and Czech), the software also contains features such as serial numbers, date and time marking and password protection.

The machine comes with a comprehensive 12 months parts and labour warranty, with additional optional maintenance contracts tailored to individual customer requirements.

The Base and Column facilitate the manual z-axis adjustment to allow for components of differing heights. Riser blocks are also available for marking very tall parts.

Powered digital Z axis with autosense system are available: see models 3000 C150-150ZA.

The 3000 Controller is a separate unit to ensure it is protected from the mechanical shock loading of the marking operation. The easy to use software allows for 5 font types and up to 1350 layouts to be stored. Available in a variety of languages (including English, French, German, Spanish, Swedish, Finnish, Italian, Portuguese, Cyrillic and Czech), the software also contains features such as serial numbering, date and time marking and password protection.

The machine comes with a comprehensive parts and labour warranty, with additional optional maintenance contracts tailored to individual customer requirements.

Other machines in this range feature a variety of marking areas to ensure the marking head suits exactly the requirements of the application.

- Marktronic 3000 C150-150ZAV Marking window: 150 mm x 150 mm

- Marktronic 3000 C300-150ZAV Marking window: 300 mm x 150 mm

If larger marking areas are required for your application then consider the 3000 GantryMark™ range of machines.

Wide Range of Options

Standard hardware options include :

- Magnetic table

- Machine ‘T’ slot table

- Label fixture

- Custom designed fixtures are also available on request

- Remote Start/Stop box

- Footswitch start pedal

- Automatic Label feeders (Electric and Pneumatic)

- 100mm & Custom Extended Nosepiece and Styli

- Barcode scanner to simplify data entry

- Pneumatic Deep Marking Attachment

- Circumferential Axis for marking around cylindrical parts (80mm chuck)

- Through hole circumferential fixture (122mm chuck)

- 0 – 90° Tilting Heavy Duty Circumferential Axis (200mm chuck)

- DataMouse™ Pro Direct Part Mark DataMatrix Reader (PC Required)

- Extended Warranty packages available.