With the in-house facility for design, engineering, manufacturing, controls & software, SmartMark® is capable enough & most competent to offer completely tooled up fully automated design-to-ordersolutions for variety of applications in wide industry segments such has Automotive, Auto Ancillary, General Engineering, Defense, Aerospace, Food & Pharmaceutical industries.

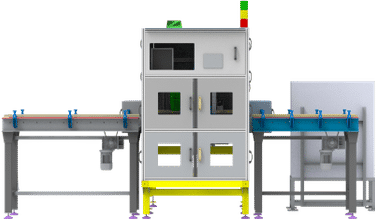

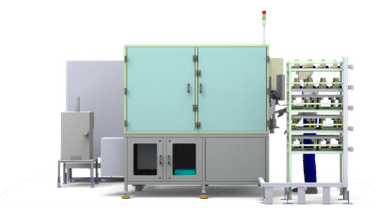

- Custom built total solutions, Semi-automatic, Fully automatic tooled up systems.

- Customized integration for SAP/ERP/ORACLE & cloud communication.

- Supply of completely tooled up solutions with all necessary Electronics, PLC control panels, hardware and software’s etc.

- Detailed Applications Study.

- Conceptualization, Engineering and Design.

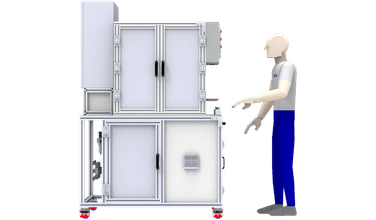

- Tryouts at SmartMark®.

- Installation & commissioning of equipment including training & handover of complete technical documents.

- AMC Support.